“Now it is time to board the ship. At my bunk I quickly change out of my "blues" and into my overall, scarf, and leather helmet. I pull on my sneakers, and then hurry forward along the keel catwalk and out to my engine gondola. The order comes through to test the engines. In a few minutes, the four Daimler-Benz diesel engines begin the prelude to the long concert that awaits them. The dust in the hangar swirls and the ship begins to tremble like a racehorse ready to charge out of its gate. Then it is quiet in the hangar again, with only the sounds of the ground crew working diligently to make sure that everything is ready. We then stand on the catwalk leading to the access hatch into the ship and talk about this and that until we hear the command "all aboard".

The command comes, and since I'm on watch I go into my gondola. Soon afterward comes the long-awaited order, "Airship march!" Slowly and ponderously, the airship is hauled from the hangar, drawn by the able hands of the ground crew. Handkerchiefs flutter, and I see the Flughafen cafeteria once more and for a moment I imagine a glass of Dortmunder sitting in front of me. I chase that thought away – now it's time to work, and that means that I have to pay attention so that everything goes smoothly.

The ship is brought about so that it is facing into the wind. The passengers are all aboard, and an S.A. band plays a spirited march. Suddenly the ground is dropping away beneath us and the inevitable "Muss I Denn Zum Städtele Hinaus" plays. We're on our way.

The bell on the engine telegraph rings, and the lever shifts to "Marsch". I grab the throttle and the propeller begins turning, first slowly and fitfully, then after a few seconds and a couple of knocks, the engine is running. It quickly revs up, black smoke streams out of the exhaust tubes, and the ship begins moving forward.”

Thus began a typical Hindenburg flight, described here by trainee engine mechanic Theodor Ritter. making his very first (and, as it turned out, only) transatlantic crossing – May 3rd to May 6th, 1937.

Engine mechanics comprised by far the largest group of crew members aboard the Hindenburg. A minimum of 15 mechanics were carried on each flight, which allowed for a three-watch rotation in each of the four outboard engine gondolas, plus three floaters for the Trimm Wach rotation (see below). The engine mechanics were responsible for the operation and maintenance of the Hindenburg's four Daimler-Benz 16-cylinder LOF-6 diesel engines. The engines were started using compressed air, and were also designed for direct switchover from forward to reverse and back again, also by means of compressed air.

The engine cars themselves were referred to by number, beginning with the starboard aft car (#1), portside aft (#2), starboard forward (#3), and portside forward (#4). Each engine mechanic was assigned to a specific engine for the duration of a given flight. For the Hindenburg’s earliest flights, the engine car assignments tended to be fairly consistent: Josef Schreibmüller, Eugen Bentele and Hermann Rothfuss in car #1, Eugen Schäuble, Richard Halder and August Deutschle in #2, Wilhelm Dimmler, German Zettel and Willi Scheef in #3, and Raphael Schädler, Adolf Fischer and either Walter Banholzer or Wilhelm Döbler in #4. However, as the 1936 flight season progressed, new men were added to the mechanics roster while Schäuble, Dimmler and Schädler transitioned over to flight engineer roles, and the engine car assignments became less static.

New mechanics were typically recruited from the Daimler-Benz motor works in Untertürkheim (where the LOF-6 was produced) just as the older mechanics who had previously served aboard the Graf Zeppelin had mostly been drawn from the Maybach factory in Friedrichshafen, which had produced the Graf’s VL-2 engines. The idea was to have the ship's engines manned by men who had built them and spent months working on them in the factory. By the time an engine mechanic began serving aboard the Hindenburg, he was intimately familiar with the ship's engines.

A Mechanic’s Life

Engine mechanics stood a two-hour watch during the day, and three at night, and their time on duty was adjusted so that each mechanic would go on watch at the same time every fourth day. In addition, as the Hindenburg passed from one time zone to the next during transatlantic flights, engine mechanic watches would be extended or shortened by half an hour to account for the time difference.

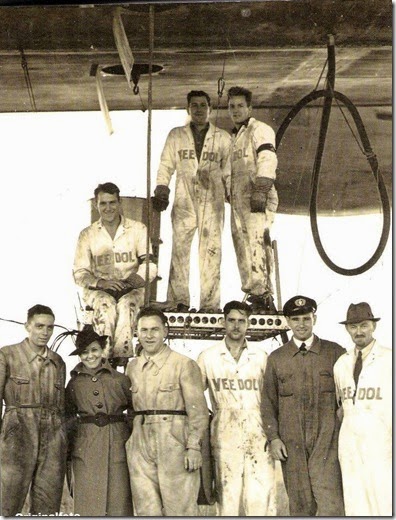

All engine mechanics (and all members of the maintenance crew, including the riggers an the electricians) wore a grey cotton one-piece overall while working in the ship’s interior. The overall was free of any buttons or metal fastenings that might strike sparks against the ship’s framework, and mechanics also wore rubber-soled sneakers to provide further protection against an errant cobbler’s nail sparking against a girder or ladder rung. Engine mechanics on duty in the engine cars also wore a leather flight helmet and goggles as well as earplugs to protect their ears from the prodigious roar of the engines.

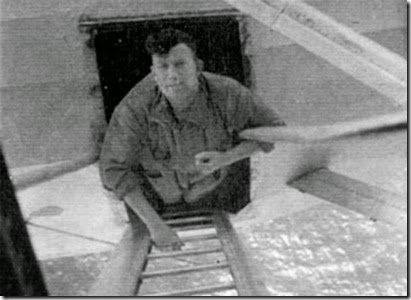

To reach their engine cars, the mechanics would either climb down a ladder to reach the aft cars, or cross a short lateral catwalk to reach the forward cars. Neither was for the faint of heart. Theodor Ritter would later describe his first time traversing the catwalk to his forward portside engine car in broad daylight with the North Atlantic ocean far below. His watch at the beginning of the flight had ended at 11:00 PM the previous evening, and his walk back to the ship’s interior, in the comfort of darkness, had seemed unremarkable. His trek back across to his engine car for his watch the next morning, however, made somewhat more of an impression on him.

“I open the hatch that separates the gondola from the ship and a sharp wind blows in. It's sea air, and below me is the blue, endless ocean – nothing but water as far as the eye can see. You really get a sinking feeling the first time you are over the ocean and have to cross that tiny catwalk to the gondola. But this "Schweinehund" [inner fear] is quickly suppressed and I step across. And it goes marvelously, it's just that it's my first time.

As I walk along the short catwalk, the wind grabs hold of me, pressing my cheeks in and inflating my pockets – bad news for anything that isn't tightly fastened. The wind is very cold, and I can tell that the ship is making good speed. It's blowing the water right out of my eyes by the time I make my way across.”

Leaning into the 80 MPH slipstream, an engine mechanic (probably Adolf Fischer) makes his way across to the ship from engine car #4. (photo courtesy of the Luftschiffbau Zeppelin GmBH Archive)

The trip between the ship and the aft engine cars, which were slung lower beneath the hull, could be even more of a challenge. Chief Mechanic Eugen Bentele, a veteran of approximately 80 Graf Zeppelin flights and 50 Hindenburg flights, would later write:

“Getting into and out of the [aft] engine car when watches were changed or for repairs meant climbing along a ladder that could be folded up to make a streamlined spar. For protection from the propeller wash when climbing into the car, there was a strut which you could hook your arm over. Mind you, the whole thing was a lot more difficult when you had to clamber along the ladder with an awkward, heavy engine cylinder.”

Note his arm crooked around the windward spar.

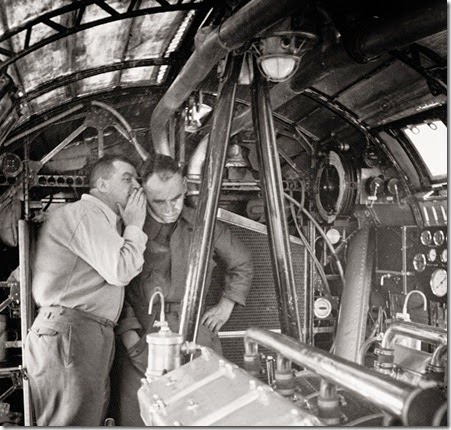

While on watch in his assigned engine car, each mechanic would monitor engine performance using the rev counter, water and oil temperature gauges, and indicators for oil level and pressure. However, it was not enough to simply watch the engine. A good mechanic also had to continuously listen to his engine – still clearly audible even through the ear protection they wore – to make sure that it was running smoothly.

This became such a habit that when a mechanic was off watch in his bunk, the noise from the engines rarely interfered with their sleep. Eugen Bentele later recalled this for his autobiography:

“The bunks for the mechanics were in the stern of the ship on either side of the gangway around which so much of our lives on board revolved. Despite the noise from the engines in the stern, we slept well – we were certainly tired enough. In fact, the change in the monotonous hum of the engines when one of them was shut down would actually wake us up.”

The noise from the engine was such, however, that verbal communication between mechanics inside the engine cars could be challenging when the motors were being run at cruising speed. Theodor Ritter would later recall that there was rarely a great deal of conversation between them when relieving one another at the end of a watch.

“I do a quick clean-up of my gondola, and my relief, Chief Mechanic Eugen Bentele, arrives at 11:00 sharp. We exchange a quick greeting. You can't really talk above the noise of the engine, so a friendly smile and I'm off.”

Though engine repairs were not uncommon, the engine mechanics often found that entire two-hour watches would pass without so much as a knock to be attended to. At these times, they would take advantage of a special fringe benefit of their engine car duty – one of the best, most expansive and unobstructed views on the entire ship. With an open aft end of the car, a pair of broad clamshell radiator shutters on the forward end that was often thrown wide open, a door-sized access hatch on the inboard side of the car and a porthole on the outboard side, the engine mechanics had their pick of vantage points from which to view the scenery that often slid by only a few hundred feet below. Forests, cities and rivers while over land, sharks and rays sunning themselves beneath the surface of the warm South Atlantic on South American flights, icebergs and even occasionally the aurora borealis while soaring high over the North Atlantic on voyages to the United States… the engine mechanics had no shortage of amazing sights to occupy their time during a particularly quiet watch, and some of them even took photos with small Leica cameras that they could tuck safely away inside their overalls for the wind-swept trek between the ship and the engine car.

(photo courtesy of the Luftschiffbau Zeppelin GmBH Archive)

Off-Duty

With each mechanic’s watch lasting two to three hours, depending on the time of day, there wasn’t a lot of time for off-duty socialization. “And so it goes – work, eat, sleep, work,” Theodor Ritter would later write. When one’s engine car watch was over and the mechanic’s relief arrived, he usually lost little time in getting some chow and hitting his bunk for a few hours’ sleep. Ritter described this very well in his memoir:

“Soon I'm hanging up my overall and my leather helmet on the hook by my bunk, and then I go down to the washroom to wash my hands. Seldom does a mechanic leave his gondola without dirty, oily fingers, unless he has kept them in his pockets the whole time he was on duty. It has been known to have happened!

Now comes the enjoyable part. The crew's mess smells so enticing that you couldn't pass it by if your life depended on it. So, you have a cup (or five) of coffee or tea, and a good-sized helping of sausage or kippers, cheese, jelly, et cetera. After I have fortified myself, I walk contentedly back along the keel gangway. I joke good naturedly with the men on keel watch, and talk turns to how sad the girls in Frankfurt must be, or whether "she" will be at the airfield at Lakehurst. Naturally, this is all out of the question for me, since I've been raised well and I'm already engaged!

Back in the crew's quarters, my bunkmate Fred Stöckle is already sawing a huge log, practically drowning out the humming of the engines. Quickly, I get out of my clothes and into some warm pajamas, because it is still somewhat cool. Then I pull the camel-hair blanket over my head and soon I'm in the realm of dreams. I am off watch until 5:00 in the morning, so I can get plenty of sleep. One of the men on keel watch wakes me up. The next morning I'm woken rather roughly at about 4:30, but we're not babes in diapers anymore. So it's up, wash, have breakfast, and then into the gondola right at 5:00.”

The mechanics’ bunks were almost all the way aft along the keel, directly beneath gas cell #5. Unlike on the LZ 127 Graf Zeppelin, on which there were only enough crew bunks to accommodate the off-watch men, the Hindenburg had sufficient sleeping space so that each man theoretically had his own bunk – theoretically, because the ship often carried extra trainees, and because by the end of 1936 another section of crew bunks just aft of the passenger decks had been removed to make room for additional passenger cabins. Still, the mechanics had plenty of space to get as much sleep as their watch rotation allowed, and there was even a row of windows along each side of the keel through which the men could watch the scenery as they drifted off to sleep.

The mechanics on standby watch also shared shipwide cleaning and sanitation duties with the rest of the crew, and would assist with repairs and other projects as the need arose. But for the most part, life aboard the Hindenburg for an engine mechanic was very much as Theodor Ritter described – work, eat, sleep, work.

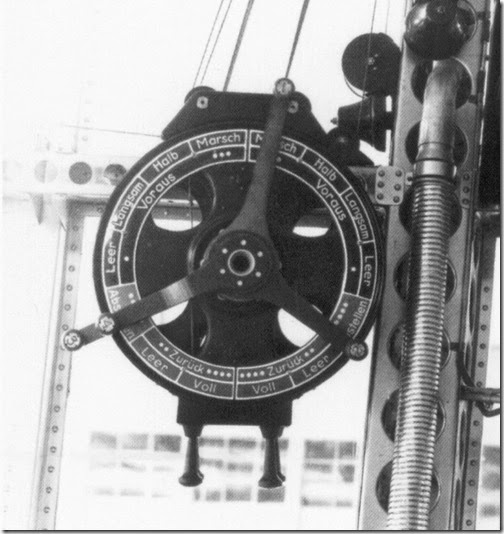

Engine Telegraphs

Engine speed was generally determined by the watch officer, whose orders were transmitted from the control car to each engine gondola via a mechanical ship's telegraph. The mechanic on watch in a given engine car would then adjust the speed of his engine accordingly. Much as with telegraphs on ocean-going vessels, The Hindenburg’s watch officers would pull a toggle to ring a bell in the corresponding engine cars a certain number of times to indicate a given engine speed, and then move the indicator handle for that engine to the correct dial position. Forward (Voraus) engine speeds included Leer (idle – one bell), Langsam (slow), Halb (half) and Marsch (full or cruising speed – three bells) while reverse settings included merely Leer (idle – two bells) and Voll (full – four bells). There was, of course, also an Abstellen setting (five bells) to order that an engine be stopped.

Once the mechanic on duty had received a telegraph order in his engine car, he would respond by repeating the order on the telegraph and ringing the bell accordingly as confirmation that the order had been received.

Most speed adjustments occurred during landings and takeoffs, when changes in engine speed and direction were needed to maneuver the ship to or from the hangar or the mooring mast. However, there would occasionally be instances during flight when the engines needed to be slowed or stopped on orders from the control car for things like mail drops or to give the passengers an opportunity to get a good look at a particularly noteworthy sight.

The mechanics would also maintain communication via telegraph with the ship’s main engineering station, located amidships on the starboard side of the keel, so that the Chief Engineer could be kept apprised of the current state of each engine. In addition to specific settings showing the general speed of each engine, under the general dial indication Drehzahl (“engine speed”) there were also settings that indicated the current revolutions-per-minute at which a given engine was operating. Standard cruising speed was 1350 RPM, which produced 820 horsepower for a forward airspeed of 125 kilometers per hour (approximately 67 knots, or 76 MPH). The engines could also be set at maximum speed (indicated by the telegraph setting “A.K.” or Äußerste Kraft – full power) for short periods of time, generating 1400 RPM from the engines.

Complete List Of Engine Car Telegraph Settings

Voraus (Forward): Leer (idle), Langsam (slow), Halb (half), Marsch (full)

Zurück (Reverse): Leer (idle), Voll (full)

Abstellen (Stop)

Drehzahl (Revolutions): Leer (idle), 1200, 1250, 1300, 1325, 1350, 1375, A.K.(1400)

Ablösung (Relief)

Pressluft (Compressed air)

Motor Unklar (Motor inoperable/not ready)

In-Flight Repairs

Telegraph communications with the engineering station were usually in connection with repairs of some sort. This was, after all, one of an engine mechanic's primary duties – to monitor their engine for problems, and to fix these problems when they arose.

“Of course,” senior engine mechanic Eugen Bentele would later recall, “during repairs all three of the engine mechanics for that car had to get to work. If your luck was out and there was a big repair when you were off duty, you had to go for a night without sleep.

Perhaps the most significant of these major in-flight repairs occurred during the Hindenburg’s first round-trip transatlantic flight to and from South America, which took place between March 31 and April 10, 1936. It is a prime example of the dedication, expertise and inventiveness that was the mark of a Zeppelin mechanic.

The Hindenburg had made her first test flight less than a month earlier, on March 3, and her final 12-hour test flight had been canceled in favor of a three-day propaganda flight over Germany, as ordered by the Ministry of Propaganda in Berlin. Many of the Hindenburg’s crew members derided this type of propaganda and publicity activity, calling them “circus flights.” But as the Nazi government had funded a great deal of the Hindenburg’s construction, and had thereafter absorbed control of Zeppelin flight operations into the Air Ministry under the auspices of the Deutsche Zeppelin-Reederei (DZR), Berlin was able to call the shots as they saw fit. Thus, on March 31st, the Hindenburg set out on her first transoceanic flight without having been subjected to full-speed engine tests.

During the flight to Rio, the mechanics in all four engine cars had noticed that their motors were burning more and more oil, and that they were throwing bright blue exhaust as well as smoke from the housing vents. During their stopover in Rio, they removed the cylinders from the engines and noted that a significant amount of carbon buildup had caused the piston rings to stick in their grooves, and some had actually seized up.

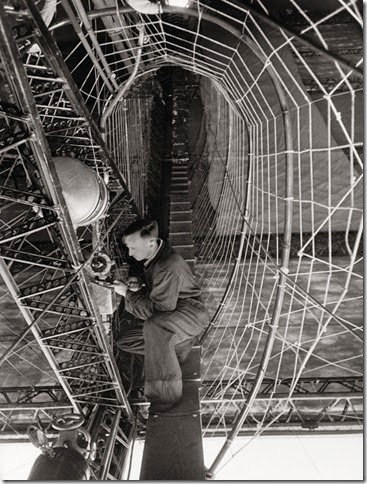

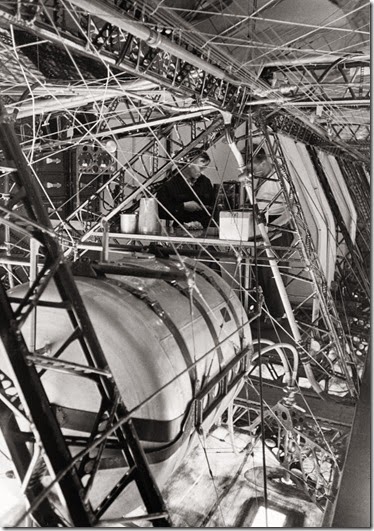

repair benches alongside the keel walkway during one of the Hindenburg’s early flights. (photo courtesy of the Luftschiffbau Zeppelin GmBH Archive)

Mechanic Richard Halder also looked into the crankshaft housing on one of the engines and discovered that the shank had snapped on one of the four connecting rod bearing bolts. Since they didn’t happen to have a spare aboard, nor was there one to be found at the airfield, Chief Mechanic German Zettel improvised a new bolt from a lathe tool, and the mechanics hoped that it would suffice for the flight home. To be on the safe side, they refrained from running that particular engine at full speed for the duration of the flight.

However, the damage the mechanics repaired while at the airfield in Rio was only the beginning of their troubles.

Eugen Bentele would later describe the additional engine problems that they suffered during their flight back to Germany:

“One engine [engine #4, portside forward] was shut down between St. Paul’s Rock and the Cape Verde Islands because it started to run unevenly. After taking off one row of cylinders we found that a gudgeon pin had broken. Replacing one of these normally took about an hour. But because the broken pin had caused the connecting rod to bend, the cylinder couldn’t be put back on. Our rough-and-ready attempt at using a crowbar to bend the rod back into shape was unsuccessful, and so we used a reamer we had on board to file the connecting rod bush till it was oval, but this still left the piston out of line.

Heaven helps those who help themselves, and our last resort was to use an aluminum rasp to remove enough metal from the top left and bottom right of the piston so we could fit the cylinder back on. The injection pump was adjusted so that the cylinder only received half as much fuel as the others, and the engine ran until we landed, although not at full power. In all, the repairs took 16 hours.

Whilst repairs on the gudgeon pin were continuing, another engine [engine #2, portside aft] spluttered to a halt and wouldn’t restart. After inspecting it, we found the bolts securing another connecting rod bearing had broken and the bearing was so badly damaged that the engine had seized up. This was now critical for the control of the ship, because we were butting into a northeast trade wind, and it seemed this would carry on all the way to Gibraltar.”We mechanics had no intention of giving up. After all, we were flying on only two engines! August Grözinger, our experienced flight engineer, came up with the solution. He had been in Zeppelins since before the first World War, and had cracked many hard nuts in his time. He suggested sawing through the damaged connecting rod above the seized bearing and running the engine on two pistons less.

The engine housing vents on both sides of the crankshaft housing were removed and two mechanics, one lying on either side of the engine, set about trying to saw through the chrome-nickel steel of the connecting rod with a normal hacksaw blade. Each mechanic worked for an hour at a time, and after 30 hours, the rod was cut. Although the engine started, it was so rough at high speeds that it was only to be used in emergencies. Luckily our old enemy the Mistral wasn’t blowing, and we were able to fly quickly up the Rhône valley to Basel on only two and a half engines.”

After the flight, the engineers at Daimler-Benz identified two design flaws in the connecting rod bolts that had led to fatigue failure. The bolt threads had been cut with a sharp root and the bolt itself had been drilled out – likely to save weight, as was common practice in airship design. Replacement bolts with round-cut threads and a solid core were created and installed, and the breakage problem did not recur.

The ship’s engine mechanics, meanwhile, had determined that the issue with the seized piston rings had been caused by bubbles forming in the coolant on its way through the cooling system and collecting near the cylinder head, causing the pistons to overheat. The mechanics corrected this by extending the coolant circuit to allow the coolant more time to settle.

Thus, when unexpected problems arose, a Zeppelin mechanic often had to exercise his engineering instincts in addition to his operational expertise with his engine. And, in fact, most of the Hindenburg’s flight engineers, to whom the Chief Mechanics reported, had started out as engine mechanics.

Trimm Wach

In addition to the watch rotation for each of the four engine cars, there was a separate fifth designation on the Hindenburg’s flight logs for engine mechanics assigned to what was listed as Trimm Wach – trim watch. Oddly, the specific duties of the men on trim watch do not seem to have been recorded in any detail. This crew designation is not covered in the DZR crew handbook from 1937, and sadly, none of the three men who served on trim watch on the last flight (Robert Moser, Albert Holderried and Alois Reisacher) survived the crash at Lakehurst to describe their duties to the U.S. Commerce Department’s Board of Inquiry.

It was, however, a distinct crew assignment from that of the engine mechanics and the flight engineers, and had its own watch rotation. This much can be confirmed by looking at crew lists from the Hindenburg's various flights. Most of the men assigned to trim watch served as engine mechanics on other flights, although some, like Robert Moser, tended to be on trim watch on a fairly consistent basis.

Trim watch seems to have been something similar to keel watch on the American airships, and was probably concerned largely with the transfer of fuel and water between tanks along the keel, and also out to the gravity tanks that fed the engines. Not only did the engine mechanics on duty need somebody inside the ship to keep fuel and coolant water flowing their way, but the command crew and the Chief Engineer also needed somebody to keep track of the dispersion of the ship's fuel and water supplies along the ship’s keel, so that the ship could more easily be kept in trim and as close to level in the air as possible. Various other crew members, such as the riggers, would sometimes take care of replenishing ballast bags during their standby watch, but it would seem likely that a man would be assigned to oversee the fuel and water tanks and their pumping systems on a regular basis.

leading to the access hatch for one of the forward engine cars.

(photo courtesy of the Luftschiffbau Zeppelin GmBH Archive)

The men on trim watch could also very likely have been used as "floaters" when more hands were needed for a particularly tricky repair, and they were probably also tasked with a variety of miscellaneous duties, such as waking the off-duty crew members in time for the watch change. Mechanic trainee Theodor Ritter, in a later memoir, specifically mentioned being awoken by the man on keel watch half an hour before he was due in his engine gondola.

It is possible that a trim watch assignment may have also been something of a transitional duty that allowed engine mechanics to expand their skills in preparation for eventual promotion to flight engineer. Standing watch along the ship’s keel would certainly have afforded them the opportunity to work with the flight engineers on projects that they wouldn’t have been able to take part in while monitoring the engines in the outrigger engine cars.

The keel walkway can be seen along the extreme right edge of the photo.

(photo courtesy of the Luftschiffbau Zeppelin GmBH Archive)

However, Hindenburg crew lists from late 1936 and early 1937 indicate that some new engine mechanics were initially put on trim watch duty before being assigned an engine car watch. So it’s difficult to say for certain where keel watch fell in the hierarchy of engine/engineering designations. It is entirely possible that it was simply instituted on the Hindenburg as an effective way to get flight time for a larger number of mechanics in preparation for the DZR’s expanded service.

The Trimm Wach designation doesn’t seem to have been added to the LZ 127 Graf Zeppelin’s crew roster, in all likelihood because the smaller Graf Zeppelin couldn’t carry as many passengers and crew as the Hindenburg. The Graf’s engine mechanics most likely split keel watch duty amongst themselves during standby watches. But by the time the Hindenburg entered service in 1936, there was a very real need to get crew trained and given sufficient flight time. The DZR was ramping up for a multi-airship international passenger line, with the new LZ 130 scheduled to begin test flights in autumn of 1937. This required a more intensive in-flight training schedule to ensure that there would be a large enough pool of crew members to draw from as new airships were put into service. The Hindenburg, with its significant amount of extra lifting capacity, certainly fit the bill.

Flight Engineers

The engine mechanics and the Chief Mechanics for each engine car reported to the ship’s Chief Engineer, Rudolf Sauter, and his team of flight engineers. The Hindenburg's flight engineers, of which there were usually 2-3 assigned to each flight, were to the ship's mechanics as the watch officers were to the command crew. They supervised engine mechanics and assisted with any major in-flight repairs to the engines. They were also in charge of the overall physical structure of the ship, except for maintenance of the gas cells and the outer cover, which was the duty of the riggers, and the ship's electrical systems, which were under the care of the electricians. But any mechanical or structural problems that occurred fell to the engineers to resolve.

The flight engineers also assisted the Chief Mechanics in mentoring trainees, which became more and more common as the 1936 flight season progressed and more new men were being brought up from Untertürkheim. Flight engineers stood four-hour watches, while the Chief Engineer did not stand a specific watch, but was constantly making inspection tours of the ship and was always available when needed.

On the Hindenburg’s early test flights, veteran Graf Zeppelin flight engineers August Grözinger and Albert Thasler filled the same role on the Zeppelin Company’s new flagship. By the time of the March 26-29, 1936 propaganda flight, Thasler had returned to duty on the Graf Zeppelin, and Fritz Sturm, head of the engine development team at Luftschiffbau Zeppelin, took his place – probably in part to observe how the new LOF-6 diesels performed so that further refinements could be made to future engine design. By June, however, three of the Chief Mechanics, Eugen Schäuble, Wilhelm Dimmler and Raphael Schädler, began to be rotated into the flight engineer positions. The three men, also veteran members of the Graf Zeppelin’s flight crew, were mentored by Grözinger and Sauter, and by the end of the 1936 season all three were flying as the ship’s regular crew of flight engineers.

Chief Engineer Sauter was, for all intents and purposes, the commanding officer of the maintenance department – the Hindenburg's "blue collar" crew. He was responsible for the engineers, the engine mechanics, and the electricians and held virtually autonomous authority over the maintenance department, as well as the engines and mechanical installations. If, for example, one or more of the engines had to be stopped in flight for repairs, the Chief Engineer was not required to consult with the ship's commander or the watch officers. Generally, the command crew would inquire only about how long the engine in question would be out of use.

The Chief Engineer would thoroughly inspect the ship before and after each flight, and make regular inspection tours during the flights. He also had to keep track, using a metal board in his office, of the amount of fuel and water in each tank aboard, as well as its current effect on the ship's trim. Each tank's status was indicated by a small tab that showed the tank as "Full", "Empty", or "In Use". The Chief Engineer or one of his flight engineers would routinely report to the control car on the overall status of the engines and the ship’s interior once every 12 hours.

Landing Stations

When the bell sounded for landing stations (one long bell, two short bells and one long bell), the mechanic on watch would be joined in his assigned engine car by the standby watch, and the off-watch tended to remain in the crew's mess unless otherwise ordered. This was not strictly followed, and the Chief Engineer had significant latitude in assigning specific landing stations to specific mechanics. For instance, Richard Kollmer, regardless of his watch status, would generally man the landing wheel in the lower tail fin.

During landings, the Chief Engineer took his position at the telephone at the emergency control stand in the lower tail fin, ready to relay orders to the other men stationed there. The on-watch and off-watch engineers each took landing stations in one of the engine cars, and the standby watch remained in the engineering station along the starboard side of the keel amidships.

As far as the landing stations for the crew on trim watch, this is not outlined in the DZR crew handbook either. The reported locations of the three men on trim watch at the time of the Hindenburg’s final landing approach were as follows: one man (Albert Holderried) at the crosswalk between the keel and engines 1 and 2, one man (Alois Reisacher) at the crosswalk between the keel and engines 3 and 4, and one man (Robert Moser) in the engineering center amidships. Whether or not these were standard landing stations and how this broke down by watch status, however, is unknown.

After landing, the mechanics would remain at their landing stations until the signal to secure from landing stations was sounded (three long bells.) Then the senior mechanic in each engine car drained the engine oil and cleaned the filters before running one last check of the engine and the propeller. The rest of the mechanics would assist with the loading of fuel and lubricating oil and other supplies.

Uniform Insignia

As with all other members of the Hindenburg’s crew, the engine mechanics and flight engineers all wore specific uniform insignias on their dress blues and their tropical whites. All wore a brass badge denoting their branch of service, and the engineers also wore sleeve stripes and cap cords as an insignia of rank. Per the 1936 DZR crew’s manual, uniform insignias for engine mechanics and the engineering staff were as follows:

Mechanics:

Branch of service badge: Gold stamped cog wheel (large for chief mechanics)

Engineers:

Branch of service badge: Large gold stamped cog wheel

(gold stamped lightning bolt if promoted from electrical personnel.)

Insignia of rank:

Chief Engineer – Three gold sleeve stripes (on shoulder boards for white jacket)

Thin gold cap cord

Second Engineer – Two gold sleeve stripes (on shoulder boards for white jacket.)

Thin gold cap cord

Third Engineer – One sleeve stripe (on shoulder boards for white jacket)

Thin gold cap cord interwoven with black

Fourth Engineer – One sleeve stripe (on shoulder boards for white jacket)

Thin gold cap cord interwoven with black

Engine Maintenance Personnel List – 1936-37

The following crewmen flew as engine mechanics and flight engineers during the Hindenburg’s 14-month operational life. Alternate duties are noted for each, as some of the men were assigned to different duties from flight to flight.

Those who served aboard the Hindenburg on her final voyage are listed in boldface.

Those who did not survive the Lakehurst disaster are listed in boldface italic.

ENGINE MECHANICS

German Zettel (Chief Mechanic)

Josef Schreibmüller (Chief Mechanic)

Eugen Bentele (Chief Mechanic)

Walter Banholzer (also trim watch)

Wilhelm Döbler (also trim watch)

Rudi Bialas (trainee)

Jonny Dörflein (also trim watch)

Hans Fiedler (also trim watch)

Adolf Fischer

Richard Halder

Albert Holderried (exclusively trim watch)

Richard Kollmer (also trim watch)

Robert Moser (also trim watch)

Alois Reisacher (exclusively trim watch)

Theodor Ritter (trainee)

Hermann Rothfuss (also trim watch)

Alfons Schäfer (also trim watch)

Willi Scheef

Wilhelm Steeb (trainee)

Alfred Stöckle (also trim watch)

CHIEF ENGINEER

Rudolf Sauter

FLIGHT ENGINEERS

Eugen Schäuble (also engine mechanic)

Wilhelm Dimmler (also engine mechanic)

Raphael Schädler (also engine mechanic)

Fritz Sturm (from Luftschiffbau Zeppelin)

![clip_image002[6] clip_image002[6]](https://blogger.googleusercontent.com/img/b/R29vZ2xl/AVvXsEiFakQQzPhrjfNIKnNu7TQ4POGsPprXi5zp7fiVGSkWvcXEb6ejLSJ57EpYoPrkSlkldKgMgQycZI9ZlYUNdbMJpT8Y8czAITOmH6KaPLWyEFImixq3pt4sWFV2e1N7DwNF_PXHDmQYm0s/?imgmax=800)